Radiant Glass Window Systems

Radiant Glass Window Systems Radiant Glass Window Systems

Radiant Glass Window Systems Radiant Heating Glass Window Technology Systems - Now with Third Generation Radiant Heating Glass for Net Zero Buildings

Radiant Heating Glass Window Technology Systems - Now with Third Generation Radiant Heating Glass for Net Zero Buildings

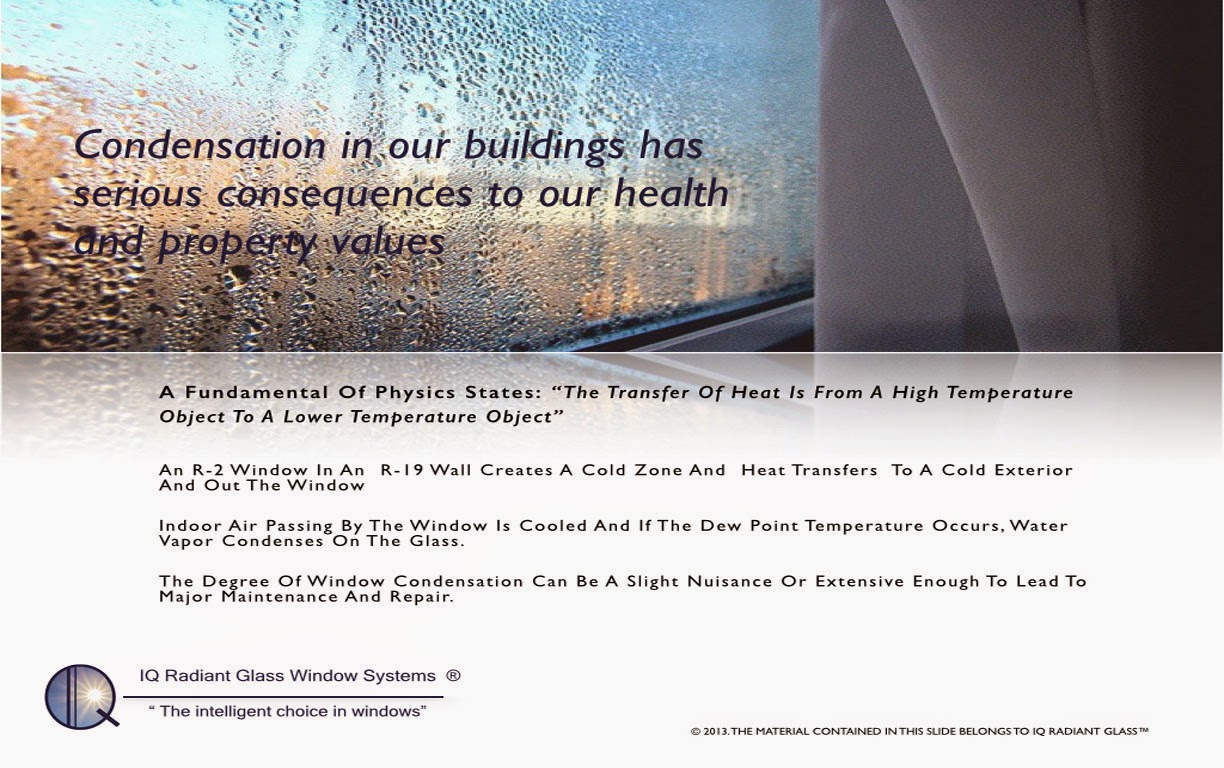

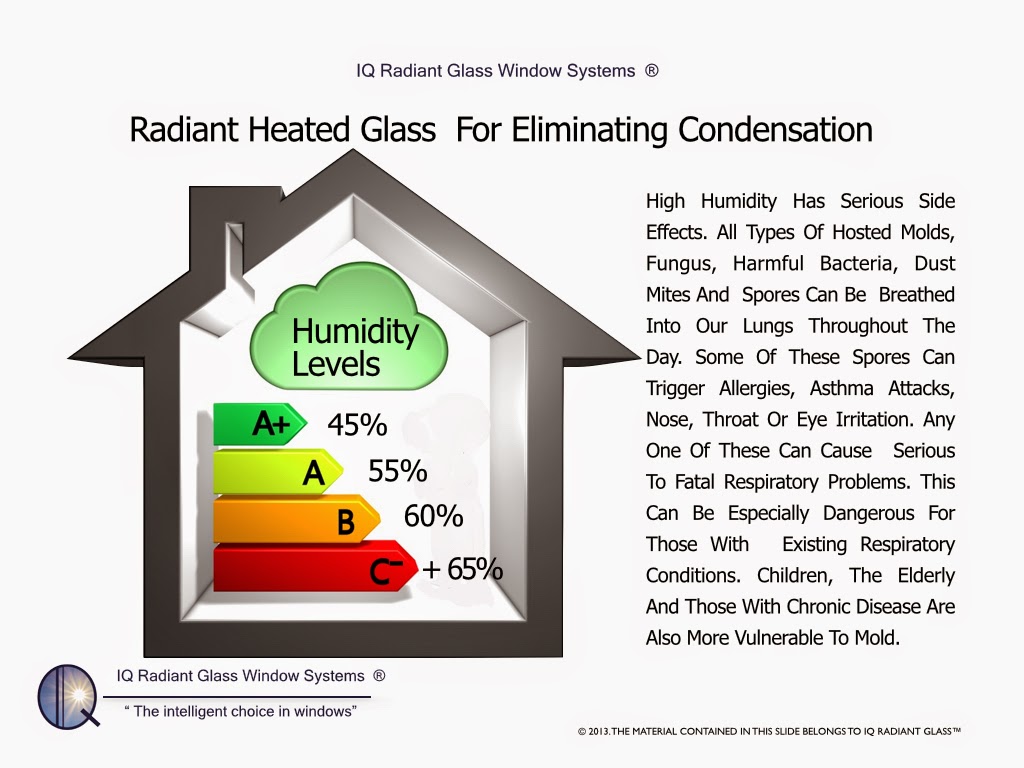

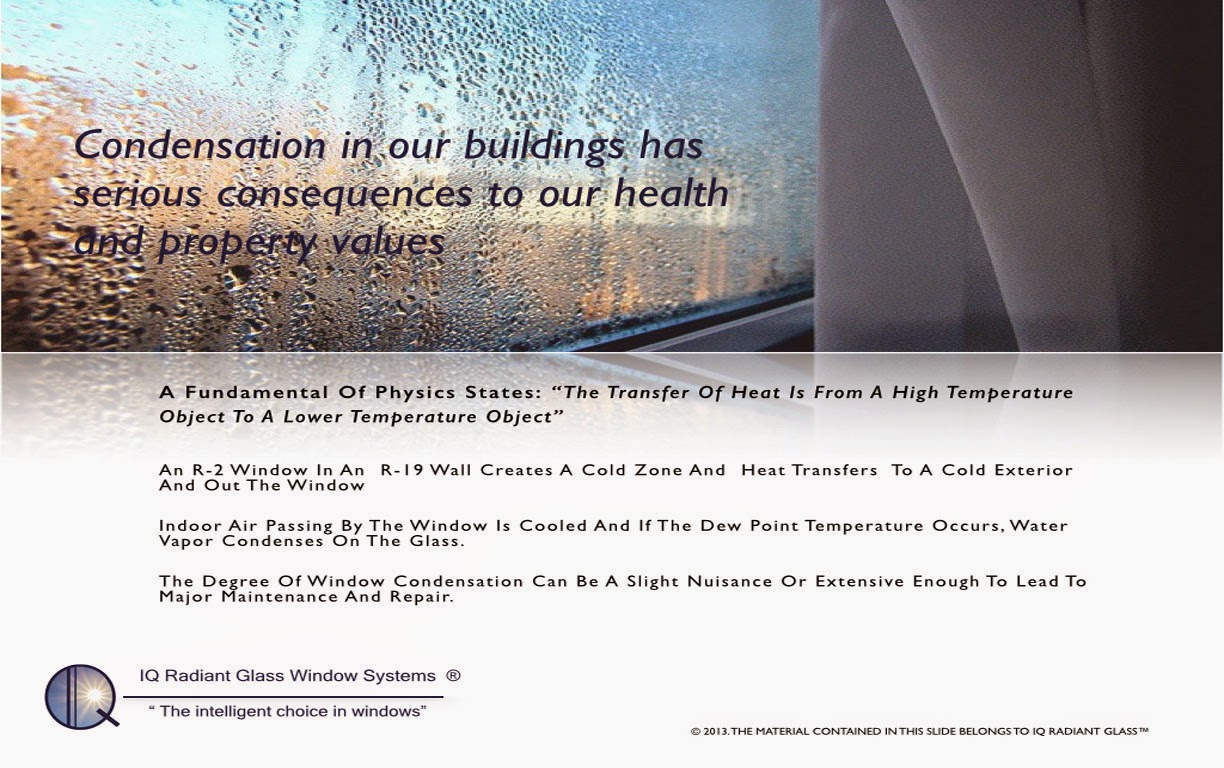

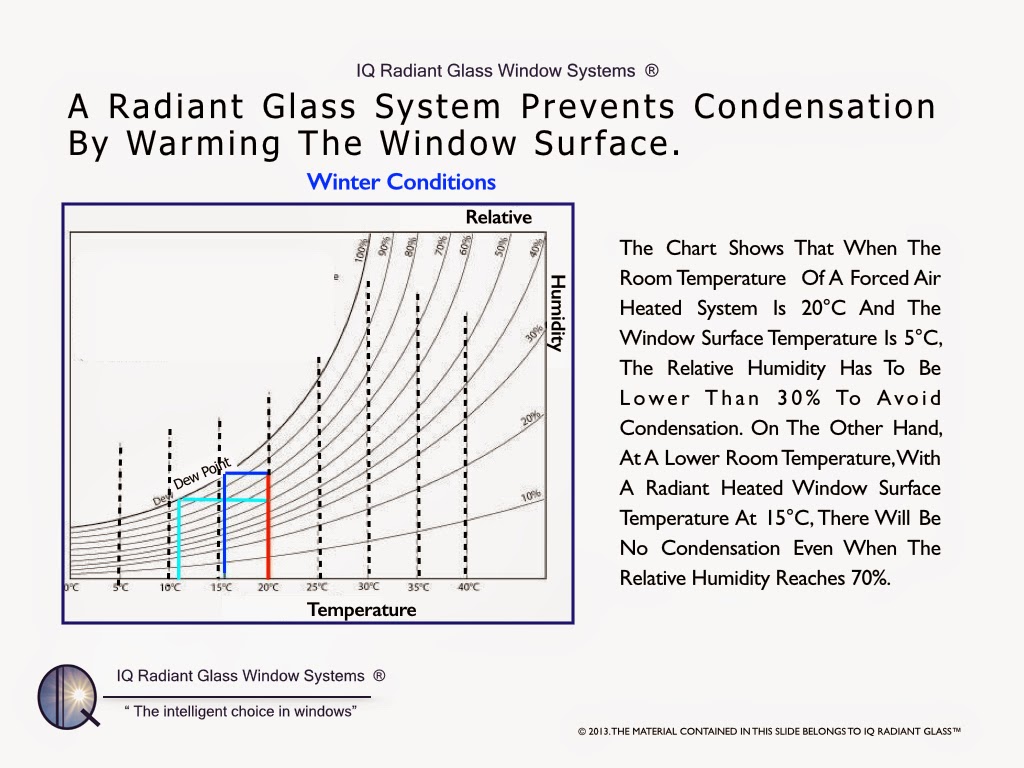

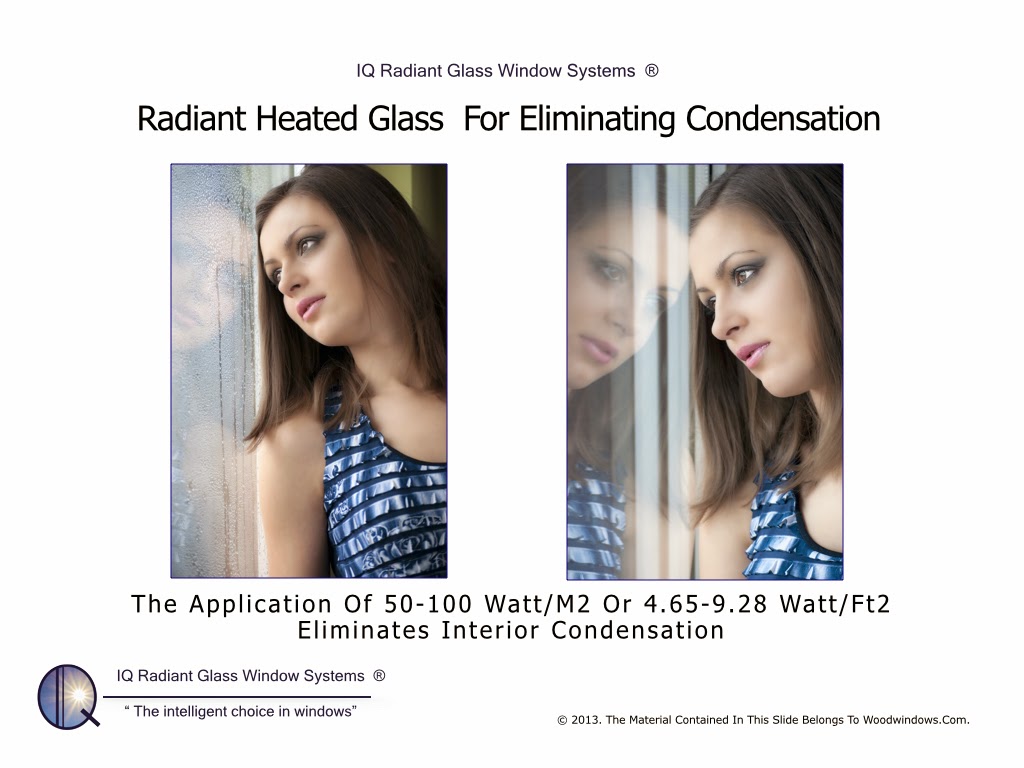

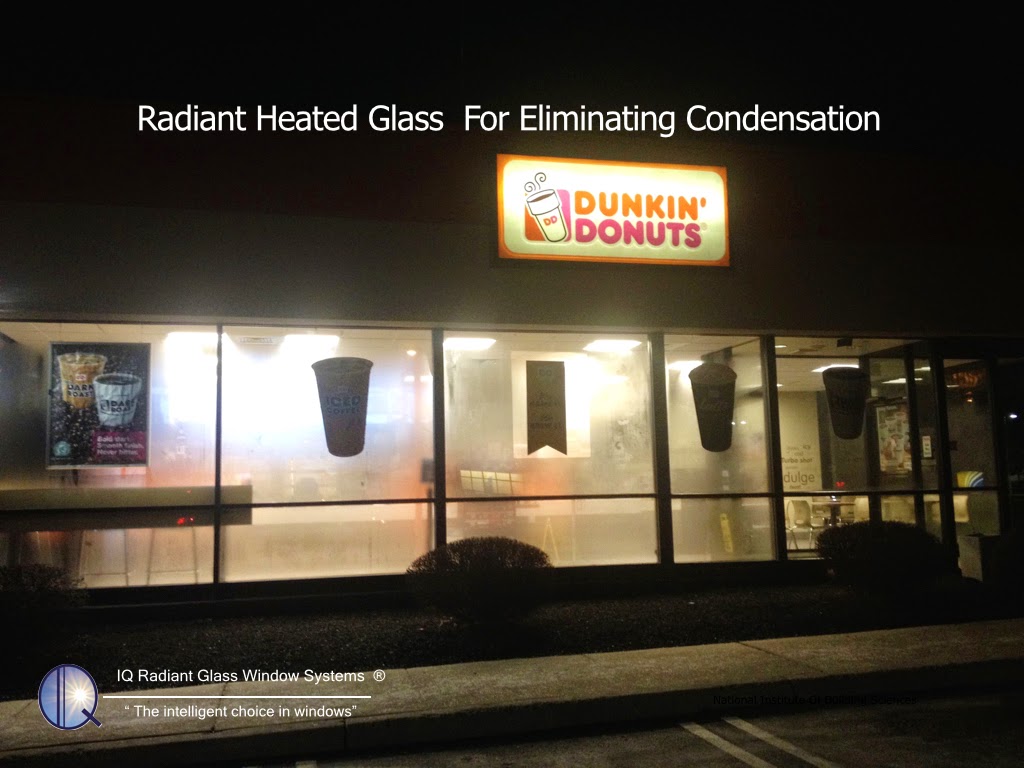

Heating glass, properly configured using the IQ Radiant Heating Glass System eliminates condensation, mold and bacteria associated with excess condensation. In this article we review how IQ Radiant Heating Glass™ can be used in critical areas such as indoor swimming pools where mold and condensation are chronic problems. IQ Radiant Heating glass is a tempered piece of glass with an invisible metal coating. The resistive qualities of the coating creates radiant heat when a controlled electric current is applied to the conductive coating. The electric current in the resistive coating generates radiant energy which warms the glass until the glass radiates heat in the infrared range. The radiant heat does not directly heat the air. IQ Radiant heating glass heats the objects and people in the room and has an efficiency at least 25% greater than forced hot air systems.

THE MOST IMPORTANT RADIANT GLASS WINDOW PROJECT EVER - SAVING THE TERRA COTTA ARMY

THE MOST IMPORTANT RADIANT GLASS WINDOW PROJECT EVER - SAVING THE TERRA COTTA ARMY

Heating glass combined with Radiant Glass Technologies, can generate R- values unmatched by any other window, regardless of frame material. In fact, the radiant heating glass can become the primary heating system eliminating the need for radiators or forced air. We can prove it with a thermal analysis of your custom design. If you are an architect, designer or construction professional, we encourage you to take the free AIA Continuing Education Course on Radiant Heated Glass Technology with the link below to the right - Contact: 866.296.5881 or sales@radiantwindows.com

First Generation Radiant Heating Glass - Two panes of metal coated pieces of low e, metal coated glass, were put together as an insulated glass unit. On side three of the IG unit, copper buss bars were fused to two of the opposing glass edges and an electric current was passed through the hard coated low e surface generating heat. The buss bars were robust in size as the thinking was to maximize the current and power handling capability of the unit. The surface heat of the glass was given priority over efficiency and the conversion ratio of electric current to radiant heat in the proper range.

Second Generation Radiant Heating Glass - It was recognized that the performance of the glass had to be maximized both on-cycle and off-cycle. To that end, inert gas replaced less efficient dry air. This increases the efficiency of the IG unit by up to 30%. To ensure the lack of distortion on the glass and to maintain at least 95% of the gas remains over the 20 year life expectancy of the unit, the manufacturing location of the glass and the installation site should be within an elevation range no greater than 2,500 feet ( 762 meters). Breather tubes, used to equalize the air pressure differential, defeat the purpose of the inert gas and are not recommended by most large glass companies such as Cardinal Glass.

Third Generation Radiant Heating Glass - Hard coated low e glass was discontinued and more efficient soft surface coatings were substituted resulting in less power usage and a refinement of the electric conversion to the optimum radiant range. Triple glazing further improved the dormant and active performance of the energized duty cycle . Increased sensitivity of control systems and pairing with solar PV panels has produced a combination that can now make Net Zero Building construction a reality. Third Generation Radiant Heating Glass Window Systems maintain a lower surface temperature, have a more efficient conversion factor and can project radiant heat over ten meters (30 feet) into the room. This is not possible with previous hard coat generations. Heat stratification was also further reduced resulting in greater thermal comfort at lower temperatures.

CEBTP, a renowned scientific control institute in France, conducted a thermal research study comparing a greenhouse heated with the traditional convection system to a green house heated with IQ Radiant Heating Glass. In identical climatological circumstances, CEBTP observed that with the convection-heated greenhouse, the air had to be heated to 77° F for the occupant to experience a sensation of warmth approximating 68° F. With IQ Radiant Heating Glass, air temperatures of only 64° F provided a sensation of warmth of 73°. In effect, IQ Radiant Heating Glass provided a feeling of 9° F more warmth with 9° less energy.

© 2015 Energwindows | All Rights Reserved